Rotary joints H

The maintenance-free all-rounder

PN max

28 bar | 406 PSI

T max

300 °C | 572 °F

n max

150,00/nominal x pressure

Flexible in use, robust and low-maintenance: The universal rotary joints of the H series are designed for a wide range of media as well as a large pressure and temperature range up to medium speeds. This means that you only need one solution for a wide range of applications. As a result, you sustainably reduce your costs for maintenance and warehousing.

- Cooling water

- Dampf

- Heat transfer oil

- Hot water

Your advantages

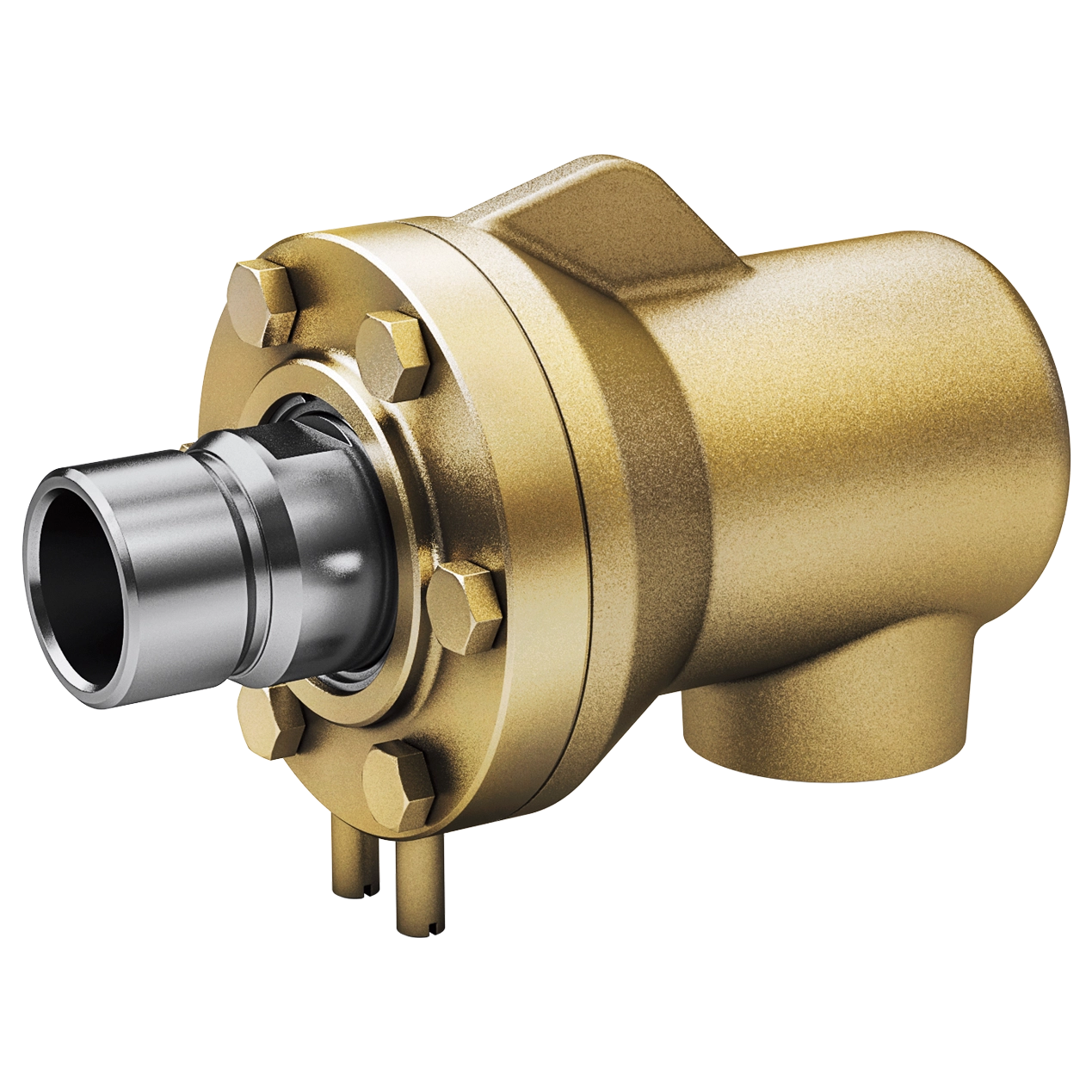

Simple

connection

The housing is mounted on the rotating rotor and is self-supporting. This eliminates the need to attach the housing to the surrounding structure. The rotary joint is precisely centered to the roller via the slider connection.

Low

repair effort

H series rotary joints are constructed from few individual parts with high availability. This enables repair without special tools at your site. You also save on storage costs, as you only need to stock wear parts.

Flexible

modular system

You assemble your rotary joint from individual components and adapt it individually to your requirements. Depending on your needs, you can, for example, change the position of the locking device or subsequently screw in flat-sealing housing flanges.

Ideal for

high temperatures

An optional nitrogen blanket helps to keep out atmospheric oxygen and thus prevent cracking of the heat transfer oil.

Maintenance-free

Self-lubricating carbon plain bearings reduce maintenance effort and costs. No greasing or re-greasing necessary during operation.

No shrinkage

necessary

For applications at low speeds and pressures, the sealing rings can already be ground in at the factory. As a result, the rotating unions operates leak-free from the start.

Higher plant availability

by wear indication

As the carbon seal ring wears, a circumferential groove appears on the rotor. You recognize upcoming maintenance and can plan in good time.

No unscrewing

for counterclockwise rotation

HWX series rotary joints with a nominal size of 65-100 have a clamping nut for the inner pipe in the housing. For left-turning rolls, the inner tube is clamped from the outside if required.

Also with

ATEX certification

For use in potentially explosive areas, we offer special versions with ATEX certification.

INFORMATION on the rotary joint H

- We have our own research and development department

- Highest quality standards in further processing thanks to modern

machining centers and assembly lines, down to the packaging - Approved manufacturer according to AD2000-HP0 and EN ISO 3834

- More than 70 patents on rotary joints

- Support during the entire product life cycle of a rotary joint

- More than 50 dealers and distributors worldwide

- 24-hour spare parts supply in all major industrialized countries

- Authorized service centers in USA, Italy, and China

- Maintenance and servicing by qualified service teams

- Repairs on site or at a maierGROUP facility

- Installation and commissioning

- Troubleshooting

We will be happy to advise you.

Please feel free to contact us!

Our team is looking forward to your inquiry.