Rotary joints

For the chemical and pharmaceutical industry

Rotary joints from the maierGROUP enable you to precisely cool and temper plants and apparatus. Even under high loads, our products operate absolutely reliably over long periods of time. You benefit from noticeable cost reductions as well as easy installation and maintenance. Our ATEX-certified rotary joints are available for processes in areas exposed to explosion hazards.

We simulate the conditions in your production in our own test laboratory and on individual test benches. This gives you the certainty that your rotary joints will exactly meet all requirements during operation.

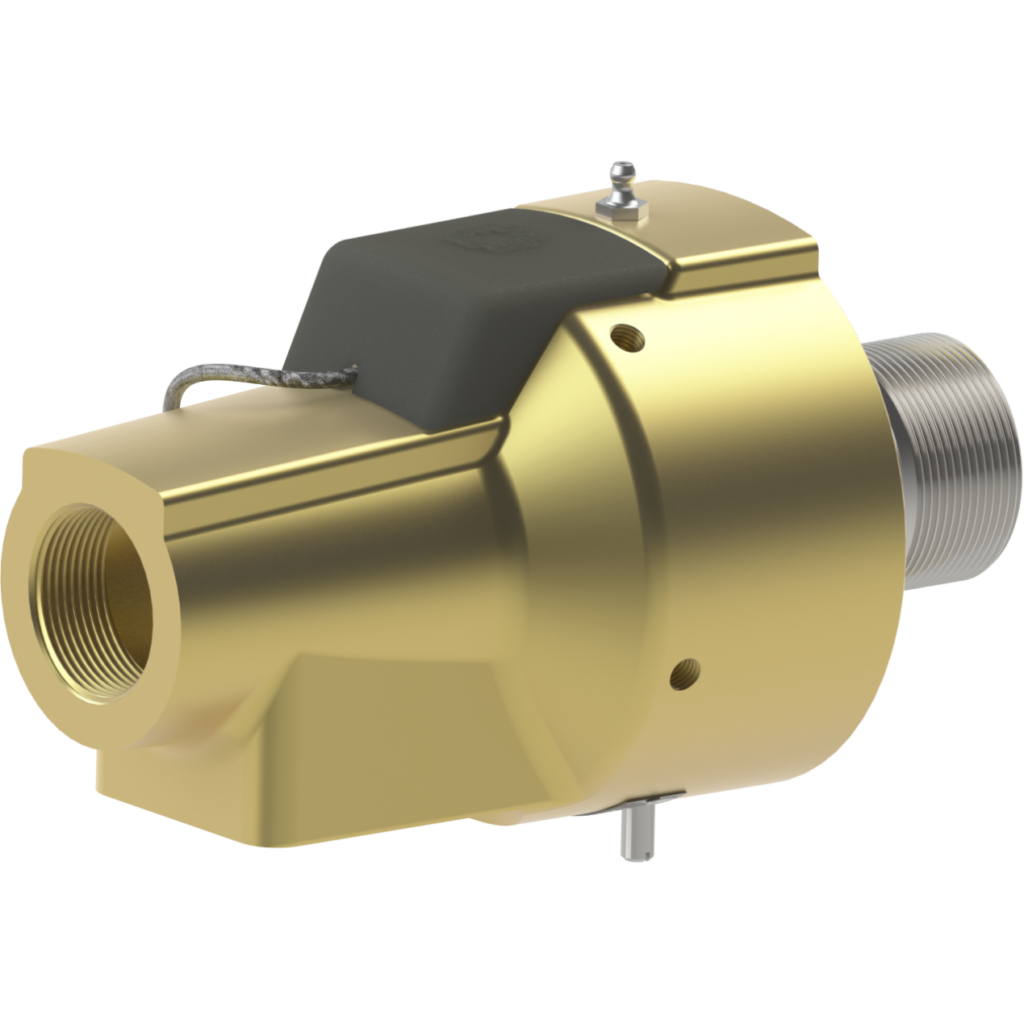

Rotary joints

for high-viscosity processes

Your application

Temperature control of kneaders and reactors with thermal oil for the production of polymers. Heating and cooling (water and glycol) of rolls, mixers, pre-calenders etc.

- Processing of tough and sticky materials such as fibers

- Intermediate products for the food industry such as baby pacifiers and diapers

- Foams for cars and mattresses

Your advantages

- High operational reliability

- Long service lives

- ATEX solutions

Your rotary joints

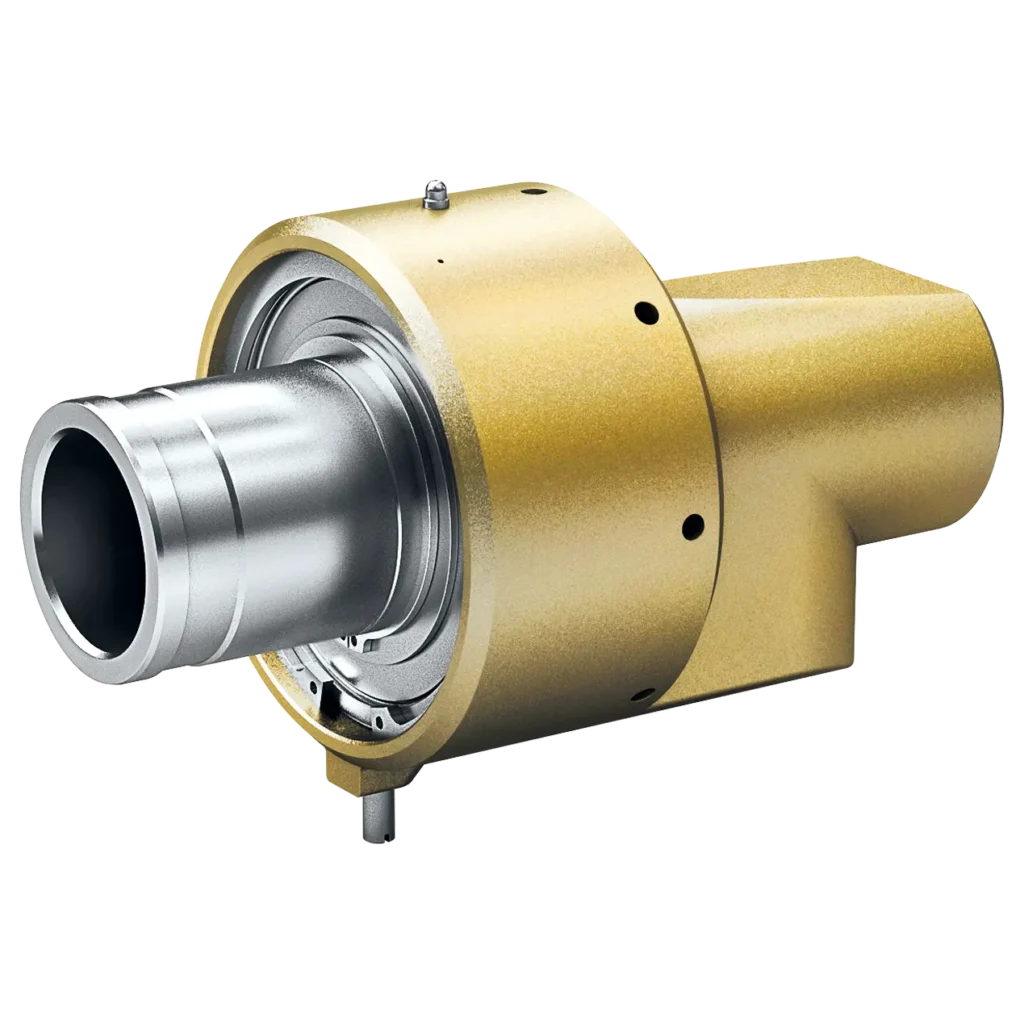

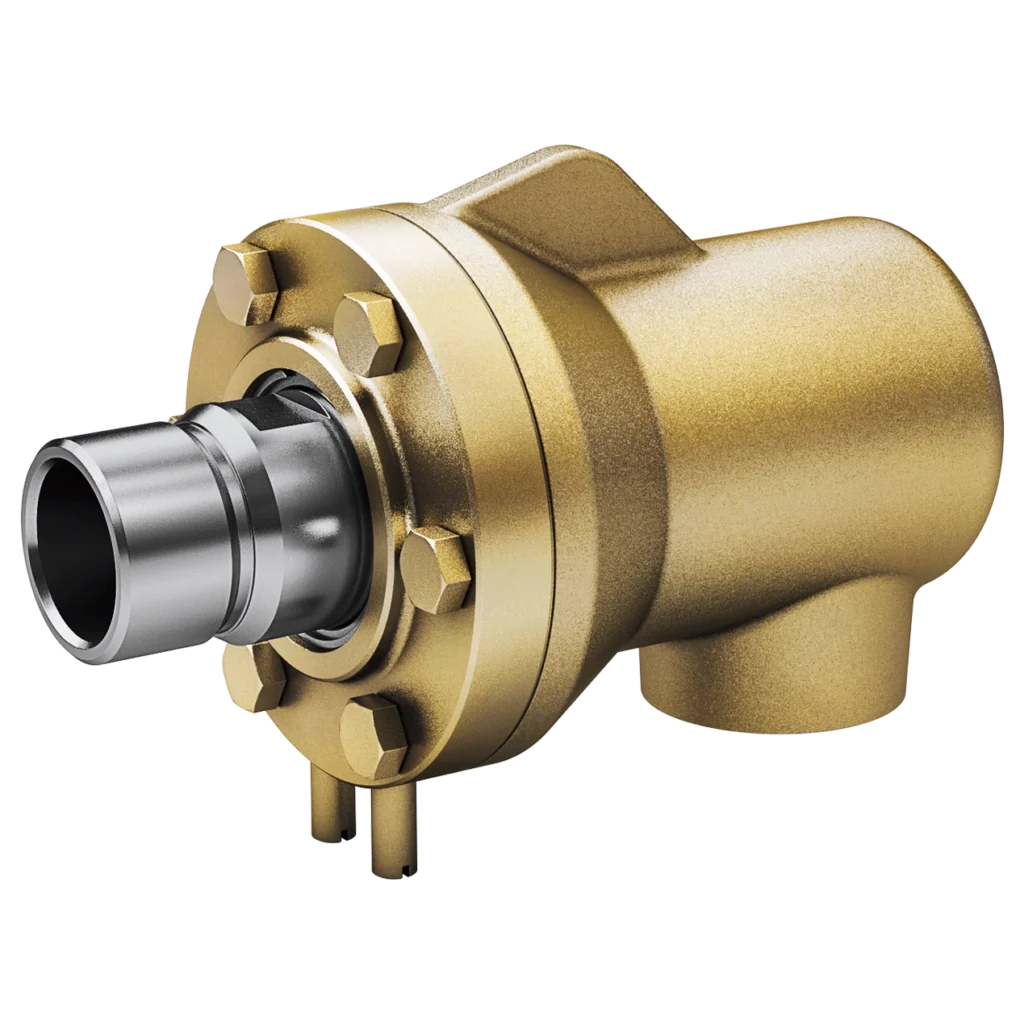

Rotary joints

for wet grinding and dispersion

Your application

Water-cooled agitator ball mills

In the production of e.g. lithium paste (for coating battery foil), but also in agrochemistry as well as in paint and varnish production, the double-walled rotor of the agitator ball mill is cooled. The flow and the return of the cooling water is carried out via maierGROUP rotary joints

- Robust roller bearing, maintenance-free up to 80°C

- Low frictional torque

- Simple installation

Your advantages

- High operational reliability

- Long service lives

- ATEX solutions

Your rotary joints

You still have questions?

Get in touch with us!

Our team is looking forward to your inquiry.