Rotary joints

for steam / condensate

Steam and condensate pose special challenges for a rotary joints. The maierGROUP offers you individual solutions, for example to specifically control the temperature of rollers and cylinders. Whether you use saturated steam or superheated steam, trust an expert in rotary joints with many years of experience.

Customized rotary joints for steam can help to significantly reduce your maintenance costs and decrease downtime. The innovative sealing technology and the certified service of the maierGROUP ensure maximum reliability and minimized energy losses of your rotary joint. Do you have very specific challenges? We would be happy to develop your rotary joint for steam as an individual special solution.

For numerous

Requirements

- Saturated steam / condensate

- Superheated steam

- One-way and two-way versions

- With or without vacuum valve

For many

Industries

- Textile industry

- Paper industry

- Chemical / Pharmaceutical industry

- Food industry

- Recycling Industry

- General engineering industry

Your

Advantages

- Corrosion-protected

- Easy to maintain or maintenance-free

- Tried and tested many times

- ATEX-certified

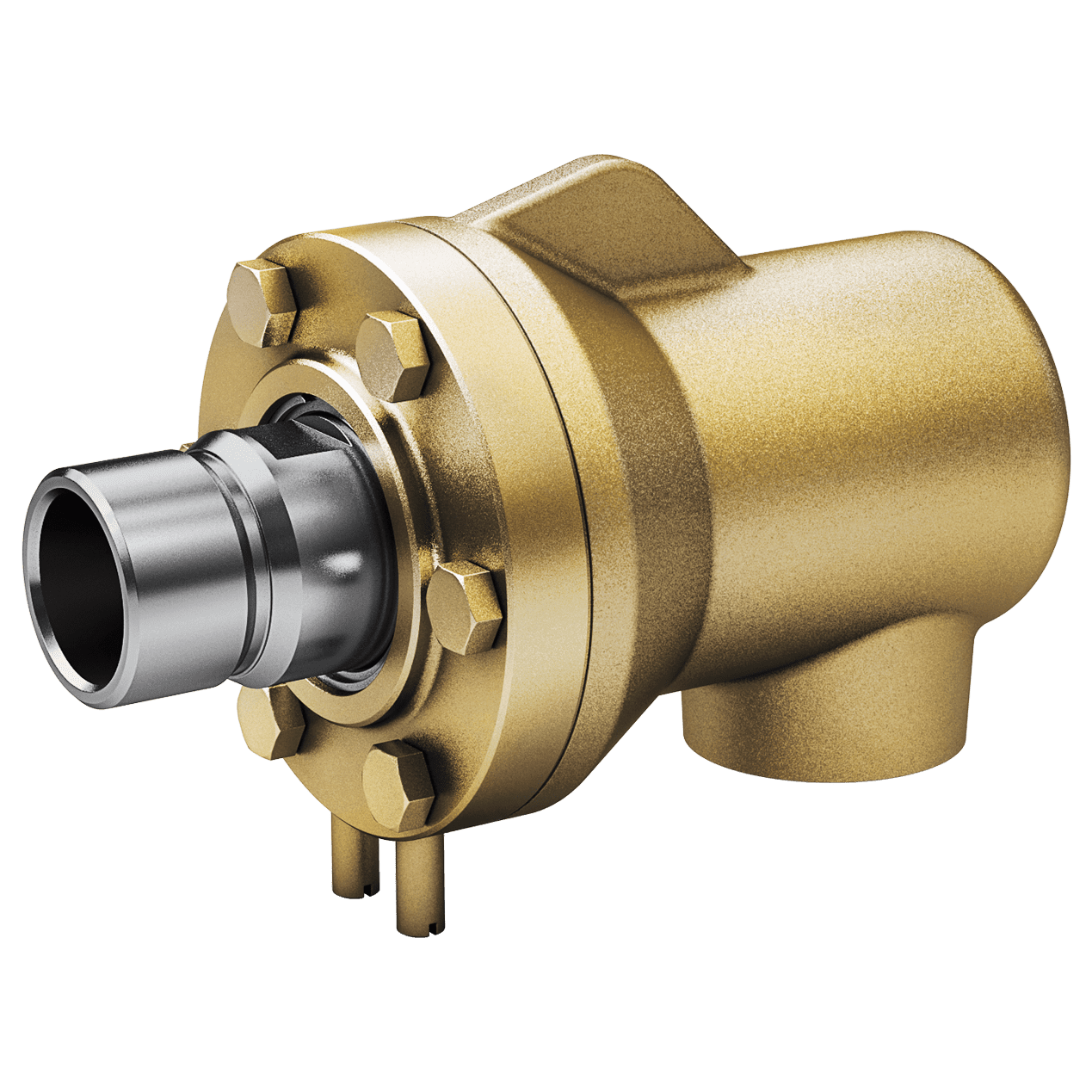

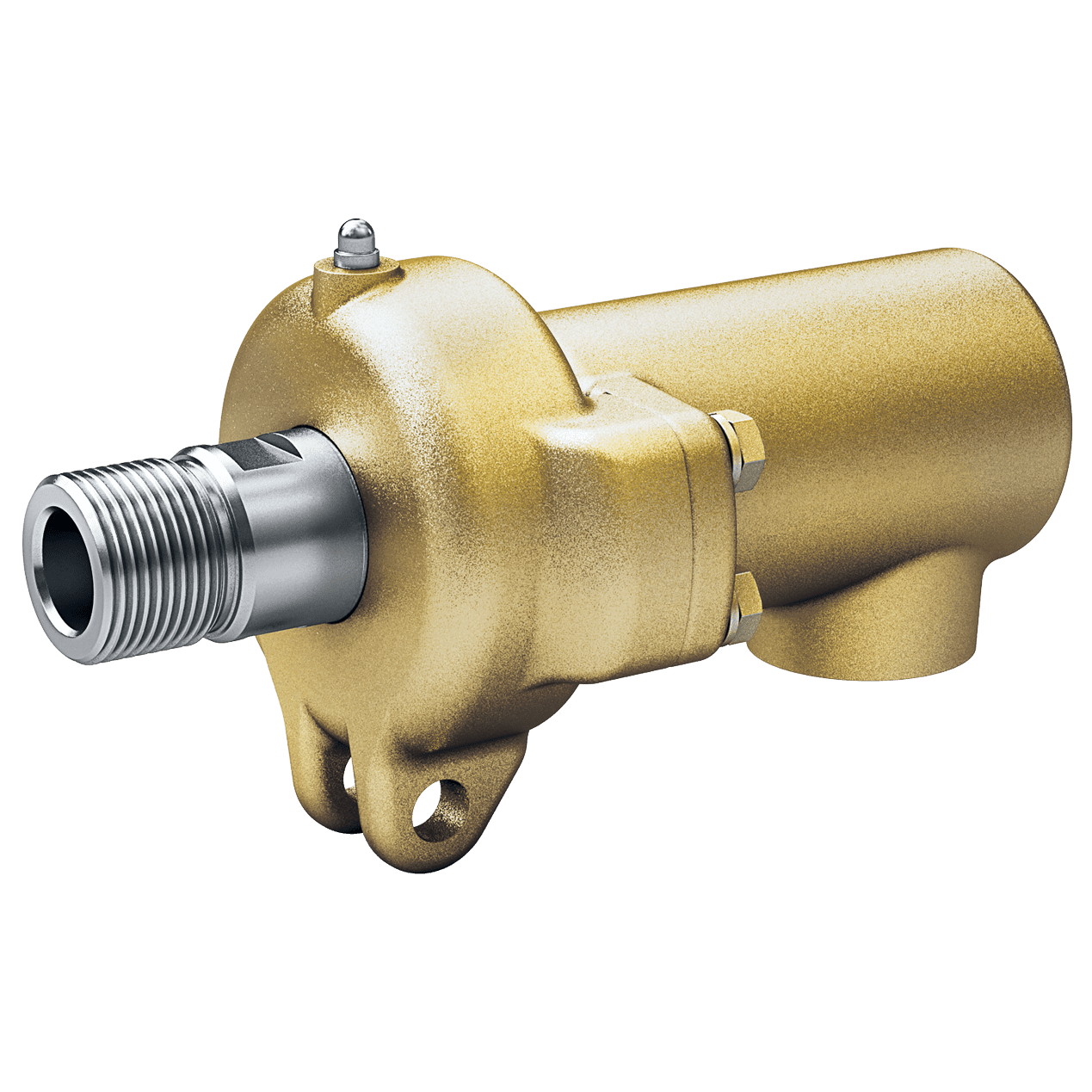

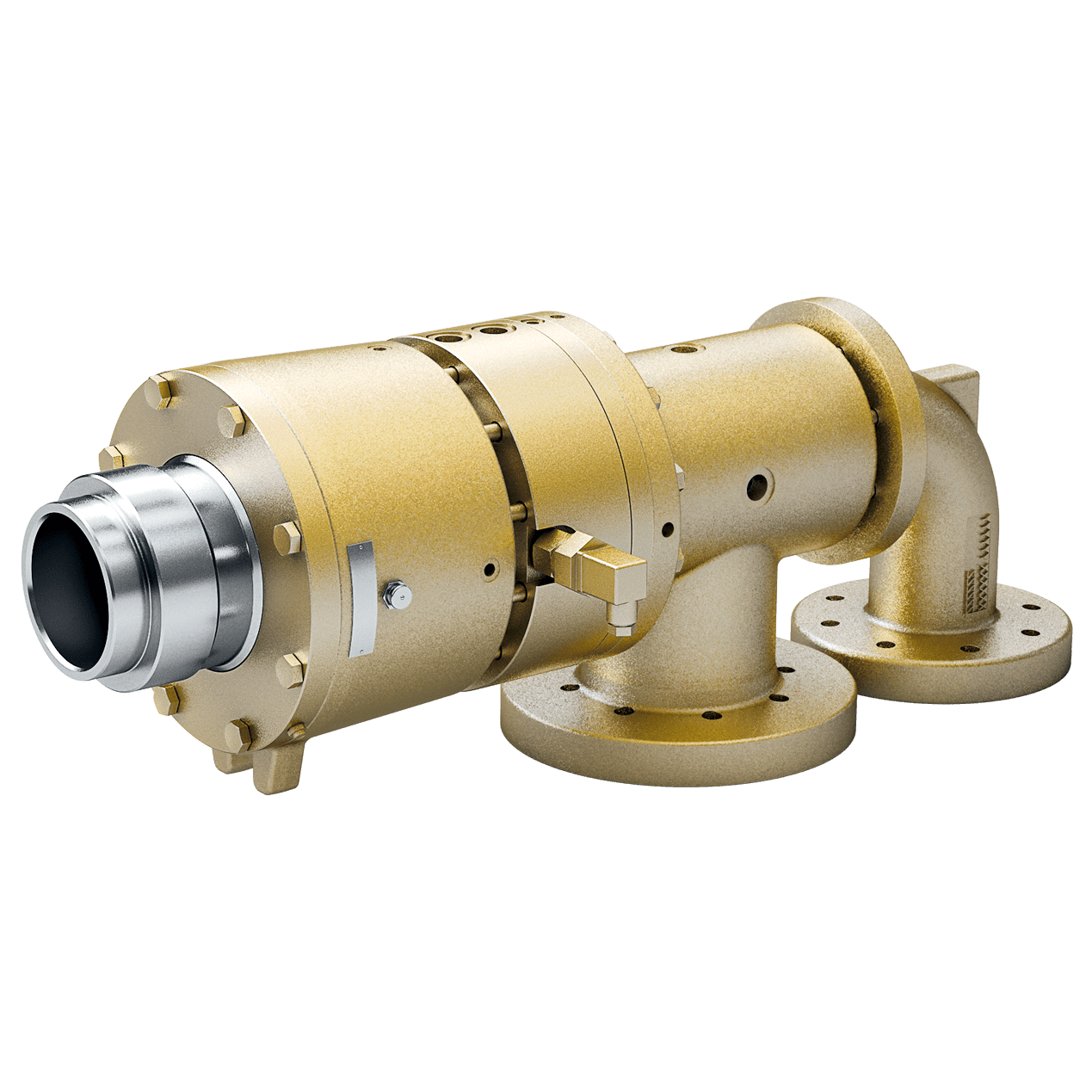

YOUR ROTARY JOINTS FOR STEAM AND CONDENSATE

DC series (special solution)

Lowest wear at the highest operating pressures and temperatures as well as very high speeds at the same time

We will be happy to advise you.

Please feel free to contact us!

Our team is looking forward to your inquiry.

GOOD REASONS

FOR THE MAIERGROUP

Decades of experience of the maierGROUP have been incorporated into the development and production of your rotary joints. We see it as our responsibility to ensure that these important components of your machine or installation perform their tasks reliably. What challenge may we tackle for you?

- 6 Standard series

- One-way and multi-way rotating joints

- Nominal sizes from 3 – 500 mm

- We have our own research and development department

- Highest quality standards in further processing thanks to modern

machining centers and assembly, down to packaging - Approved manufacturer according to AD2000-HP0 and EN ISO 3834

- More than 70 patents on rotary joints

- Support during the entire product life cycle of a rotary joint

- More than 50 dealers and distributors worldwide

- 24-hour spare parts supply in all major industrialized countries

- Authorized service centers in USA, Italy, and China

- Maintenance and servicing by qualified service teams

- Repairs on site or at a maierGROUP facility

- Installation and commissioning

- Troubleshooting